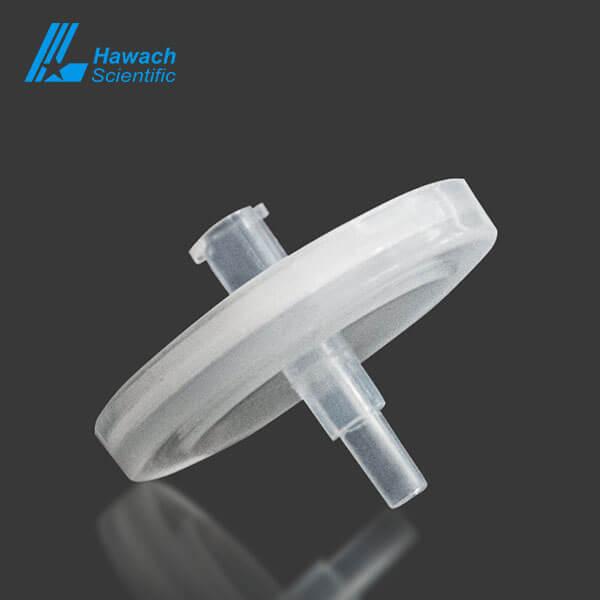

Before understanding how to use syringe filter to sterilize, we should first know the overview of sterile syringe filter. The sterile syringe filters are a fast, convenient and reliable filtering device for small volume samples used in the laboratory, which is mainly used in the pre-filtration of samples, the sterilization of laboratory biological fluid, medium and media additives. This product chooses dialysis paper, printing exquisite, gamma ray sterilization more thorough. PES syringe filter uses for HPLC solutions, sample preparation of protein-based and units for sterile aqueous filtrations. Sterile nylon syringe filters use in various analysis processes.

Hawach can use 6 sterile syringe filters types because it available 6 membrane types : MCE, NYLON, PVDF, PES, PTFE, CA, and other customized materials. Such as PTFE Syringe Filters and Sterile GF (Glass Fiber) Syringe Filters. The diameter specifications optional include 13mm, 25mm and 33mm, and the treatment capacity ranged from 0.5 mL to 200 ml. Membrane aperture specifications ranges from syringe filter 0.22μm to 0.45μm. In practical application, syringe filter 5 micron, 10 micron syringe filter is easy to use, with media shedding within limits, Gamma ray disinfection and sterilization.

Moreover, it do not need heat source and it has easy-to-tear stickers with individual independent packaging. Each syringe filter uses the most advanced PP or MBS as the housing, and the high bonding density ensures the integrity of the sample. It is of easily open outer box design, not easy to pollute. Each packing box has a batch number for easy quality tracking.

Moreover, the structure designs of the filters are precise to ensure smooth filtration. Also, the inner space is optimal to keep a very low residual rate. Normally, one of the disadvantages of traditional filters is easy to blasting. However, the sterile filters are specially designed and they can bear the blasting pressure of up to 7 bar. Now, let’s know the how to use a syringe filter.

Simply, suck up the liquid to be filtered with a syringe, insert a disposable syringe filter, and push the syringe to achieve filtration.

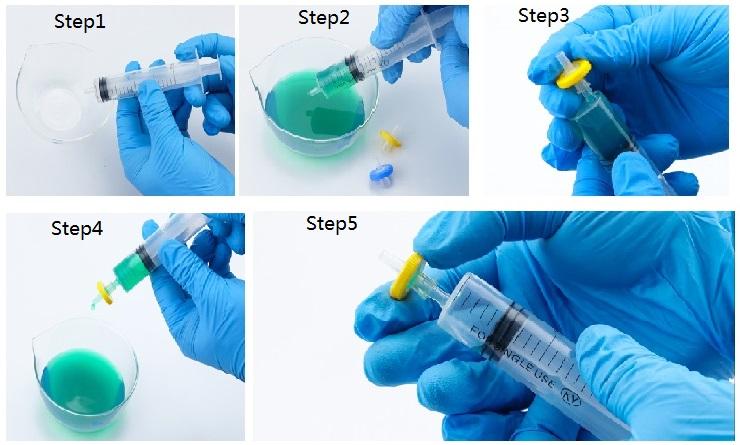

Detailed usage steps

Step 1: Use with a syringe. Before aspirating the sample, draw about 1ml of air into the syringe, which can minimize liquid residue. Step 2: Aspirate the sample into the syringe, set the syringe and remove any residue from the tip before inverting the sample. Step 3: Connect the syringe filter to the syringe and tighten gently to ensure a good seal. Step 4: Filter the sample in the syringe and inject it into the sample bottle, and then follow the steps to the maximum improve recovery rate. Step 5: Remove filter, draw air into syringe, reconnect filter tip, push out any residual sample. When you’re done using the filters, click to learn more about Cleaning And Disinfection Of Syringe Filter.

Step 1: Use with a syringe. Before aspirating the sample, draw about 1ml of air into the syringe, which can minimize liquid residue. Step 2: Aspirate the sample into the syringe, set the syringe and remove any residue from the tip before inverting the sample. Step 3: Connect the syringe filter to the syringe and tighten gently to ensure a good seal. Step 4: Filter the sample in the syringe and inject it into the sample bottle, and then follow the steps to the maximum improve recovery rate. Step 5: Remove filter, draw air into syringe, reconnect filter tip, push out any residual sample. When you’re done using the filters, click to learn more about Cleaning And Disinfection Of Syringe Filter.

Features of the sterile syringe filter

When referring to the features of the sterile filter, there are a lot of that can be summarized as per below: 1. Disinfected and sterilized by gamma ray; 2. The pore sizes of the membrane are 0.22 μm and 0.45 μm; 3. Easy to operate and the media loss can be controlled within limited bounds; 4. Every single product package has a batch number which is easy for quality trace. 5. Most of the sterile syringe filter uses Tyvek which has high effect of retaining bacteria; 6. Every serile syringe filters has an individual package with sticker that is easy to tear; 7. Basically, there are 6 types of membrane that are used in the sterile filter: MCE, Nylon, PVDF, PES, PTFE and CA;

On the whole, Hawach filter very suitable for the filtration of liquid, electronics, semiconductor industry, microelectronic water, tissue culture-medium, beverages, high-purity chemicals, water, organic solutions and other mobile phases. In addition, there is no need for the laboratory workers to replace the filter membranes and clean the filters, as a result, it can save much working time by using the sterile filters.

What are syringe filters used for ?

Mostly, the sterile filters can be used in below applications. 1. The end-filtration of ink; 2. The end-filtration of food, beverages and wine; 3. The end-filtration of high purity water of electronic industry; 4. The sterile filtration of biological and pharmaceutical industries; 5. The ultra-fast filtration of tissue culture-medium, additives and other water solutions; 6. Applications that have extremely low requirement for protein adsorption and those can improve the recovery rate of precious components.

As a convenient and reliable filter tool that is routinely used in laboratories, the syringe filter facilitates the simplification of experimental operation steps and can greatly improve work efficiency. Therefore, it is very important to scientifically master how to use the syringe filter.

1. Syringe filter sterilization, including gas filters or liquid filters, should be tested for integrity before and after use in accordance with the integrity test procedures for sterile filters. 2. After the integrity test is over, the membranes and filters used for aseptic production need to be sterilized. 3. Sterilization methods are divided into steam sterilization and ethylene oxide gas sterilization. The general method is steam sterilization. 4. For on-line steam sterilization of the filter, the pressure difference before and after the filter should be monitored during sterilization. 5. The sterile syringe filter uses can not exceed 1 working day. 6. The general filter should be kept upright and avoid tilting or lying down. 7. Record the temperature and pressure during the sterilization process, as well as the sterilization time. 8. If the filtration rate suddenly becomes faster or too slow during use, it means that the membrane has been damaged. Replace with a new membrane in time and repeat the experiment. 9. Syringe filter is not possible to filter different products at the same time, but it can be used to filter multiple batches of the same product, but an integrity test must be performed.

Click here to know How to Sterilize Syringe Filters? Several Common Materials and Advantage for Syringe Filter

Chanel earrings, CC dangle earrings in water drop shape adorned with stones and pearls v39

Chanel earrings, CC dangle earrings in water drop shape adorned with stones and pearls v39