You may have seen the episode where Marty’s WRX spun a bearing, but what exactly happens when you “spin a bearing” in a motor, and why is it so bad?

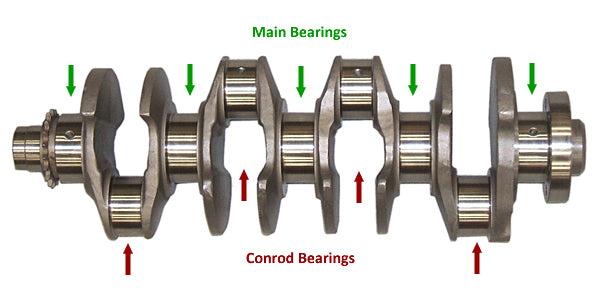

We all know traditional four-stroke piston engines rely on a crankshaft spinning in block, which also has connecting rods attaching that crankshaft to the pistons shooting up and down the cylinder bores.

The crank and rods can spin at high-speed without melting together because they sit in specially-measured bearings that have a micron-thin amount of oil lubricating the spinning metal. You might have seen shows where people built engines and they talk about bearing clearance and measuring – this measuring is critical for bearings as they rely on a thin film of oil that comes through the oil passeges in the block and lubricate the crank and rod bearings as the engine spins.

When that oil film runs dry, or if the bearing stops spinning due to another problem, the high-speed all these parts spin at means the damage is instantaneous and catastrophic. The familiar knocking noise (AKA “rod knock”) is the connecting rod banging around on the crankshaft doing horrific damage.

The best case scenario for fixing a spun bearing is you’ll replace the crank, rods and pistons, but the block is often also toast so you need a complete new bottom-end on your motor. Sometimes the bearing catches on the crank and starts spinning with the crankshaft, which builds an intense amount of heat that can lead to con rods snapping and blowing the entire block apart.

Subarus seem to be at a higher risk of these failures due to several issues with the EJ-series engines. Firstly, the physical size of the bearings used is quite small so there is less margin of error if an engine is suffering detonation or oil control issues.

Secondly, oil control (both flow and temperature) isn’t great in the horizontally opposed Subaru engines, and this means that a well-sorted street car can generate cornering loads that cause oil pressure to drop, leading to bearings failing. Part of this comes from the sump design, the horizontal-layout of the motor offering poor oil drain-back rates, and from side-load on the con rods themselves as they spin around the crank.

Pinging, or pre-detonation from improper tuning or running too hard in extreme, hot conditions, overloads the bearings in many Subaru motors. In the early days of EJ motors when they used cast pistons the ring-land on the piston was the first part to fail from detonation, but as Subaru moved to forged pistons and con rods in their factory motors those parts were able to handle the abuse while the bearings weren’t.

Changing your oil frequently (at least every 5000km/6months), not revving your car to redline regularly, and checking the level weekly are two ways to prevent bearing issues in your Subaru. Some people will add an extra 100-150ml of oil above the full level just for security when they are going to a track day, and don’t skimp on cheap oil in a Subaru!