Question: Can the LS3 engine, one of GM’s newest offerings in it’s LS family of performance engines and certainly one of its strongest, stand up to the challenge that boost presents? To find out, we spoke with some of the leading engine builders in the country to find out just how tough the LS3 is, and what sort of upgrades are necessary to keep the engine together when aiming for horsepower levels ranging from 500 to an insane 800 horsepower.

The LS3

In 2008, GM introduced the new 6.2-liter LS3 engine in the Chevrolet Corvette, creating a lot of buzz in the process. With its whopping SAE-rated 436 naturally-aspirated horses and 428 ft. lbs of torque, Corvette enthusiasts were licking their chops to get their hands on the new powerplant. The LS3 was the latest addition to the LSX family of GM high performance V8 engines, and benefited from the knowledge gathered over the years from its predecessors.

The first of the Generation IV engines, the LS2, was introduced as the base power plant for the 2005 Corvette and produced 400 horsepower. The LS3 is a great progression on the LS2, which it replaced upon its introduction, and is still considered to be a GM Generation IV architecture small-block engine that shares two key design elements with GM’s original small-block V8; 90-degree cylinder angle and a 4.400-inch bore centers.

Image: GM

Strengthening of the block and reducing the rotating masses were important ingredients in the redesign of the block. The LS3 block casting is shared with the 6.2-liter L92 block that powers the Escalade and Denali trucks and LSA and LS9 supercharged applications. It features cast-in iron cylinder sleeves, however, the bore diameter is increased from 4.00-inches found in the LS2, to 4.06-inches. The LS3 block underwent casting and machining updates, resulting in 20-percent stronger bulkheads inside. The bulkhead accommodates six-bolt, cross-bolted main bearing caps that work to limit crank flex, that, in addition to a structural oil pan, stiffens the overall structure of the engine. Like all of the base LSX engines found in the Corvette, it has a 3.62-inch stroke crankshaft.

The increased bore size offers enthusiasts far more flexibility and capability for building affordable 400-plus cubic-inch engines after swapping out for a larger rotating assembly, a big plus when you’re looking for horsepower without shelling out a lot of cash.

The LS3 V-8 was introduced in 2010 as the base engine for the resurrected Camaro SS, and remains the base engine for the Corvette as well. These two cars represent GM’s primary offerings of high performance muscle cars that hot rodders and car enthusiasts naturally gravitate to to satisfy their craving for making power and getting places in a hurry.

Image: GM

Getting Boosted

Turbocharger and supercharger kits are probably the most common method of achieving substantial horsepower gains with the LS-based engines, and one of the things we see discussed on LSX forums most often is component selection for the short block and long block of a proposed build that will feed off of boost from one of the aforementioned power adders. With all of the structural improvements that GM incorporated into the design of the LS3 engine, from the block itself to the rotating and moving components, it would seem they are practically asking you to dive in and push the limits in search for those extra few ponies.

As we said, we went to the industry’s best brains to see what – in their professional opinion – the limits of the LS3 are and what it’d take to push GM’s “wonder kid” motor upwards to 800 horsepower!

- Livernois Motorsports, based in Dearborn Heights, MI, is one of the most established speed factories in the industry, specializing in real-world, high performance applications for GM, Chrysler, and Ford vehicles. Owner Dan Millen and his staff have become one of the premier engines shops in the LS market.

- Lingenfelter Performance Engineering, a name that is virtually synonymous with high performance Corvettes and Camaros, was founded over 30 years ago and offers services in everything from engine building, to chassis tuning and product development. LPE is one of the leading sources of high horsepower LS-based GM muscle cars.

- Thomson Automotive Engines in Wixom, MI was launched by founder Brian Thomson in 1987 and is a renowned engine shop in the LS community, with a knack for building some truly mega-horsepower, forced-induction combinations.

- Stenod Performance, another of the Michigan-based LS engine facilities, specializes in boosted street and strip applications that vary from the mild to the wild, led by the knowledge and expertise of owner Joe Borschke.

Questioning whether the LS3 block can hold up to the rigors of boost, one needs only to look to GM’s own LSA supercharged 6.2 liter V8 – found most commonly in the CTS-V. Image: GM

500 Horsepower

Reaching the 500 horsepower mark with an LS3 is really representative of the “real world” scenario for most hobbyists. It involves only a nominal increase in power from the stock rated numbers – 70hp for the Corvette and 74hp for the Camaro – and doesn’t require a huge investment of time and money in order to achieve. Basically speaking, this is the most common horsepower level for LS3 Corvette and Camaro owners.

The LS3 engine is built around a strong cast aluminum block with 6-bolt main caps and internal components with performance and the enthusiast in mind. It features a strong nodular iron crankshaft, with powdered metal forged connecting rods, and hypereutectic aluminum pistons. The LS3 benefits from years of refining in its predecessors in the LS family of engines. GM really did their homework on it’s design with a focus on strength and longevity – especially in the bottom-end – and it’s plenty capable of taking more punishment than it receives straight from the factory.

For the enterprising horsepower-seeking enthusiast to reach this mark via a power-adder, roughly 5 to 9-pounds of boost from a supercharger or turbocharger application would be needed, which is largely considered a pretty tame level of boost to push through the stock LS3 engine. Each of the engine builders that we spoke with were concise and to the point that the stock LS3 rotating assembly is more than capable of handling the boost levels to attain 500 horsepower. No “ifs,” “ands” or “buts.”

Said Livernois’ Rick LeBlanc “[To handle] 500 horsepower, there’s really nothing that we do to the engine.” LeBlanc continued “GM did a good job with the LS-series of engines. The factory LS3 bottom end is able to handle a lot of power even with a power adder when tuned properly.”

“[To get 500 horsepower] we’d run about 8- or 9-pounds of boost and know that that stock engine is going to be just fine. The LS3 [internals] will handle boost very, very well, as long as you don’t get greedy with it,” said Stenod Performance’s Joe Borschke.

Thomson Automotive Engines’ Brian Thomson agreed, explaining “A lot of guys with the new Camaros are putting boost [to] them. I think if you only put 5- or 6-pounds of boost in it, a stock LS3 will hold up.”

This Livernois-prepped supercharged LS3 sits between the inner fenders of a beautifully restored ’69 Camaro. Putting out some serious ponies for the street, this F-Body has all the luxuries of a modern powerplant while pressing out good old school horsepower. Image: Livernois Motorsports

650 Horsepower

At or around 650 horsepower with a boosted LS3, you won’t be stretching the limits of the internal components or the block. The LS3, like many of the other modern engines that are in production today, are more than strong enough to handle much of what you can throw at it, to an extent anyway. Many individuals and engine builders have pushed the LS3 into this realm of horsepower on the stock internals without fault. However, it is considered a good idea at this point to invest some money and do some overhauling of your short block.

At 650 horsepower, all our builders agreed that the stock GM crankshaft will handle boost like a champ and all agreed that there is no dire need to swap it out. For rods, some recommended stepping up to a set of steel, forged rods from reputable manufacturers such as Wiseco, or the H-Beam’s from Carillo. According to Borschke, aluminum rods are only suggested for use in full-on LS3 race motors, and unless you’re going that route, recommends sticking with steel.

Stenod Performance always upgrades customers’ engines once they exceed the 600 rear-wheel horsepower mark. These upgrades include cylinder head bolts, or most often, head studs, along with main stud bolts for additional clamping force to keep the rotating assembly from walking around.

Graham Behen, Chief Engineer at Lingenfelter Performance Engineering, explained that once you begin to push the LS3 200-plus horses beyond stock, an issue that can arise is oil blow-by caused by the excessive wearing on piston rings from the added boost.

“We have an oil/air separator, which essentially comes from the diesel engine technologies. What we do is plumb into the breather system, and return the oil from that which is pulled out of the air back into the pan with a scavenge pump. As these engines get larger and larger displacement in a smaller and smaller package size, oil control is a main problem once you start boosting these things,” said Graham.

While the LS3 block can take quite the beating, the internal components will start showing the chinks in their armor when producing power up towards 800hp. Many of our interviewed shops recommended upgrading valvetrain and custom cam grinds once reaching these levels. Image: Livernois Motorsports

800 Horsepower

800 horsepower will require between 11- and 15-pounds of boost depending upon your combination, which undoubtedly begins to stress some – if not most – of the engine’s internal components. At this level, it became a common suggestion to change out much of your rotating assembly and cylinder head components. One of the big mistakes that’s commonly made when shooting for big horsepower with the LS3 is – surprisingly enough- putting in a large duration camshaft.

Thomson urged that the stock camshaft is a pretty good fit for an LS3 employing a boosted application and should just be better left alone. He went on to say however, that you’ll want to upgrade to a stronger set of valve springs to cope with the additional boost and eradicate valve float. Along with that, he urged tossing the stock hollow-stem exhaust valves, as they considered too be weak to survive the psi produced at these degrees. He recommended opting for stronger Inconel valves that are made by Manley, SuperTech, and others or even the solid stem valve produced by Ferrea. Thomson confided, “The exhaust valves in the LS3 are pretty crummy, so you need Inconel valves or something that can take the heat.”

The stock crankshaft, even at 800 horsepower, is still very much a reliable piece when mated with strong and durable hardware (same with the aforementioned 650hp level suggestions) including aftermarket main bearings and some good main studs from a well-known brand such as ARP. The same should be considered for the cylinder head bolts, naturally, and we were encouraged to replace the bolt bolts with studs just as we were at the 650hp level.

The stock GM crankshaft has actually been pushed in the neighborhood of 1,600 horsepower without fail by shops like Stenod, and while your crank’s longevity may vary and most people will never attempt to reach that sort of mark, it can handle it. If however, if you’re inclined to spend the extra dough for a stronger piece, there are several options on the market for aftermarket steel cranks for your LS3. In addition, the steel crankshaft from the GM LSA engine that powers the Cadillac CTS-V is an option that offers some additional strength over the stock LS3 crank.

When aiming for the 800-1000 horsepower range however, the engine builders that we spoke with indicated that its common for the stock crankshaft to be swapped out in favor of an aftermarket 4.00-inch crankshaft in order to create a 414-cubic inch or similar stroker.

Our speed shops all suggested swapping the factory crankshaft out for a 4-inch stroker, as well as replacing the factory connecting rods with a set of steel H-beam rods – similar to those found in the factory-supercharged LSA and LS9 plants.

The LS3 engine comes with steel head gaskets that engine builders have pushed well beyond 800 horsepower, so whether you choose to upgrade the gaskets is mostly a personal decision. Thomson explained, “That the cometic head gaskets that are utilized in the LSA engine are considered to be a great option that his shop purchases straight from the GM catalog.”

Many engine builders, including Stenod, go the route of custom pistons rather than off-the-shelf pieces with engines pushing 800-plus horsepower. Most of the well-known manufacturers will produce a set of pistons that meet the needs of your particular combination and the kind of power you’re trying to make. Said Borschke, “When making 800 horsepower, we’re very rarely using an off-the-shelf piston. At that point, you’ve always got some sort of variable that causes you to not use an off-the-shelf piston.”

Borschke went on stating that a set of larger injectors are necessary for your fuel system, such as 82-, 84-, or even 96-pound injectors to handle the load. Along with that, at 800 and even 650 horsepower, switching to a methanol fuel injection system for the added safety in the fueling department might be a good option – although wholly impractical for street use. There are a handful of fuel systems on the market for the Corvette today, but with the newness of the Camaro, those systems haven’t quite taken off yet. As a “workaround,” Joe mentioned some have tapped into the fuel tank and put an external pump inside that runs off a hot switch, and once 4- or 5-pounds of boost is reached, it turns on and adds the additional fuel needed for the boost.

Thomson suggested placing an oil squirter on the pistons, as the LS3 has siamese bores that don’t pull any heat out of the pistons and can become a real problem when you begin to put boost to the engine. To do so, you can either machine these through the main journals like certain factory oil squirters are or install an aftermarket squirter kit. If however, you go with the 4.00-inch stroke crank, the factory squirter cannot be used, leaving aftermarket your only option.

As it was at 650 horses, the blow-by gases and oil control begins to become more of an issue, making piston ring selection imperative in addition to running the oil/air separator to limit the blow-by and crank case pressure. As far as oil pumps go, the factor LSA unit, which is the largest volume pump that GM produces, will work great on your high horsepower, forced induction LS3.

There’s no doubt that the LS3 plant – and all the LS engines, for that matter – were a great leap forward for GM. The General made all the right moves in building a foundation for power-hungry performance enthusiasts to truly build a stout powerplant. Be it nitrous, a supercharger or turbo system, the LS3 will definitely take whatever you can throw at it. Image: Stenod Performance

Conclusion

While we’ve discussed many upgrade options and suggestions for your LS3 engine build to provide proper strength and longevity to match your given horsepower goals, the defining element, like any engine, will remain your tune.

Said Borschke, “In my opinion, tuning is everything. You know, we can push a car real hard as long as it has a conservative tune in it. But once its got a real aggressive tune and you get a bad tank of gas, you could have detonation which could cause the top ring line to knock out of the piston or puncture a hole in the piston from detonation. That’s when you end up hurting your short block.”

Behen echoed that point in stating, “The biggest thing with all of this is to make sure it’s got the right fuel and the right spark so you’re not turning it towards detonation.”

The LS3 is a great engine that follows up on the success of GM’s line of LS engines that it predates, and much of what they learned from those other engine designs was integrated into this model, giving performance enthusiasts the ability to make a good bit of additional horsepower without necessitating the costs of a new block or an entire new internal assembly. To achieve 500 horsepower, you’re looking at virtually zero cost in upgrades, and at 650 just the basics such as forged rods and stronger cylinder head and main bolts studs. Even at upwards of 800 horsepower, many of your stock pieces are still up to the test, although it’s advisable to upgrade much of your rotating assembly.

Affordable horsepower with the knowledge that you’ve got a strong bullet beneath you, it’s a win-win.

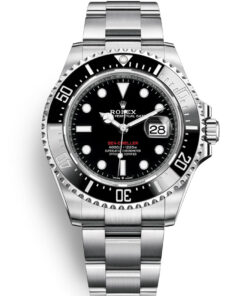

Rolex Sea-Dweller 126603 Bi Colour

Rolex Sea-Dweller 126603 Bi Colour  Rolex Sea-Dweller 126600 Mk1

Rolex Sea-Dweller 126600 Mk1